Description

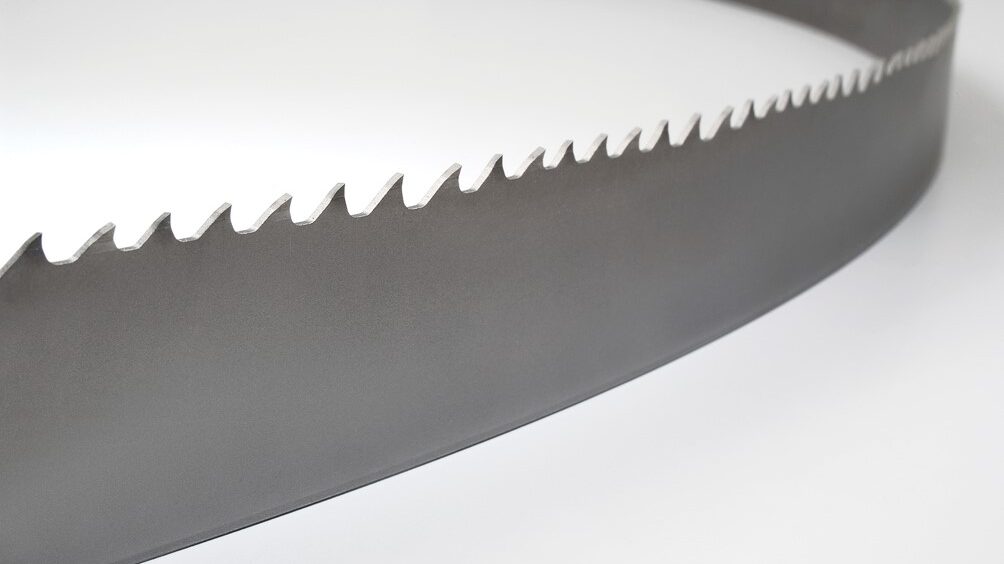

Bandsaw blades have evolved over the years to offer higher production rates, consistent performance, and more precise cutting.

New designs and innovations provide a variety of blade types to meet your needs, such as bi-metal blades and carbide tipped.

Whether your process needs to cut metal piping or industrial foam, our team of experts can help you find the right blade to fit the application. We can determine the blade type, tooth specs, speeds, and feeds to achieve optimum performance in your cutting process. We represent all major brands of bandsaws like Lenox, Simmons, and more.

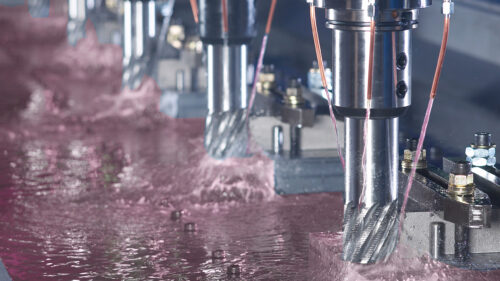

SurfacePrep now also has authorized and certified bandsaw weld centers at our locations in Dallas, Texas and Chandler, Arizona to support our customers. Coil blade stock is cut to length, welded, and finished. This reduces lead times and inventory levels for our customers, saving time and resources.